Which is Better for HVAC Systems

Carbon Steel vs. Stainless Steel

With our expertise in various HVAC products, from bladder expansion tanks to fabricated flow diverters, American Wheatley is a trusted source for material selection. We use two common metals—carbon steel and stainless steel, in our HVAC applications, and we understand the importance of choosing the suitable material for your specific system’s application and performance goals. This blog delves into the properties of each metal, providing you with the knowledge you need to make an informed decision.

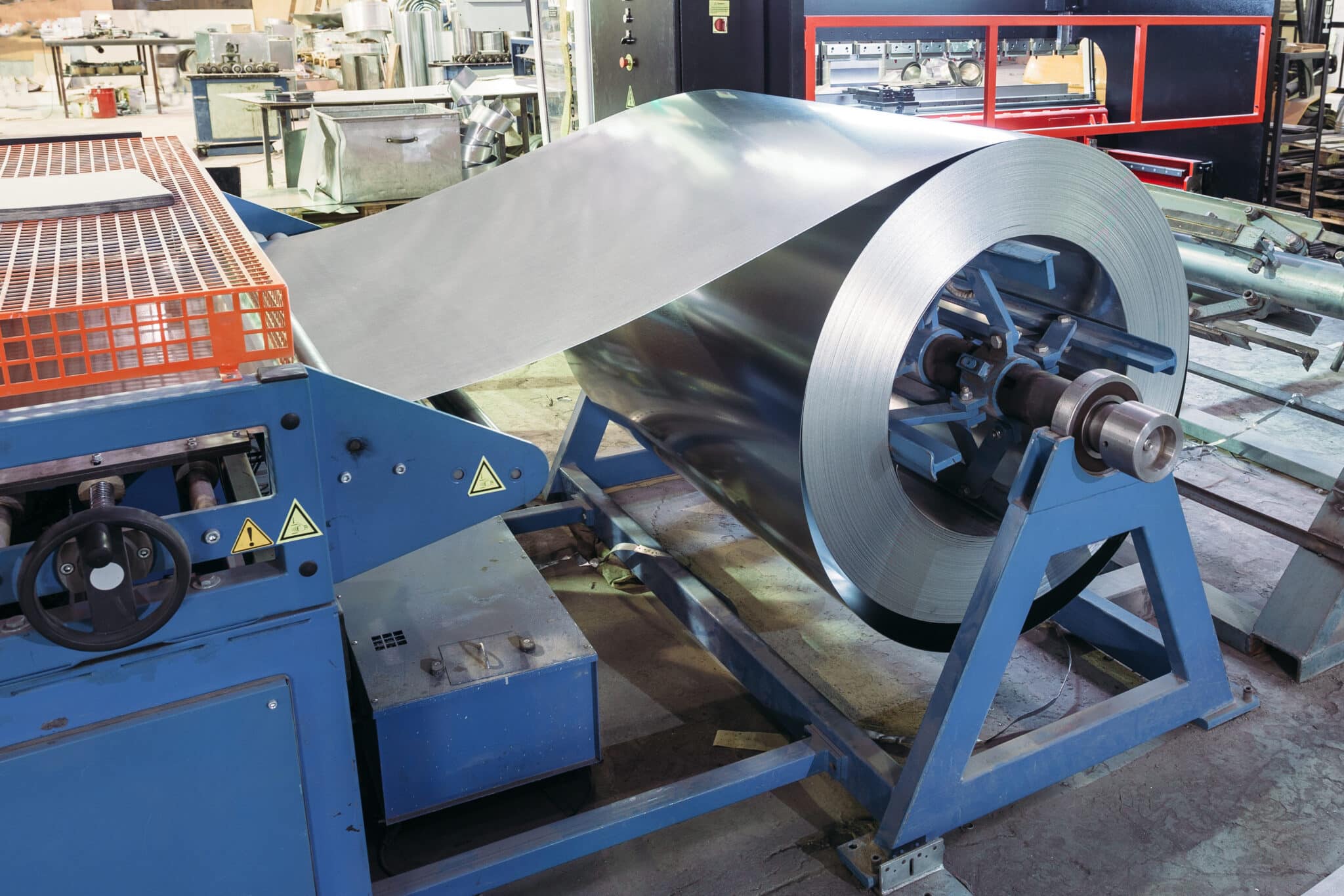

Carbon Steel

Carbon steel is a standard option for many HVAC systems due to its excellent structural integrity, making it durable under various mechanical pressures. Additionally, it is lighter than other materials, often making it easier to maneuver and install. Given its high thermal conductivity, carbon steel adjusts quickly to temperature changes and effectively maintains elevated temperatures. It is also easily accessible and less expensive, making it optimal for projects with time or budget constraints. However, carbon steel requires more maintenance, and exposure to certain elements can cause corrosion or rust. So, if it is not maintained correctly, carbon steel has a shortened lifespan.

Stainless Steel

Stainless steel, another standard selection for HVAC systems, offers versatility in various applications. At American Wheatley, we offer two types of stainless steel for our hydronic components: Type 304 and Type 316, each with slight differences in chemical composition but similar performance. While not as physically durable as carbon steel, stainless steel still provides plenty of strength and reliability in HVAC systems. Its high corrosion resistance and suitability for potable water, hydronic, and indoor and outdoor environments make it a reassuring choice for your HVAC needs.

Fabrication Process

When a fabrication shop uses carbon and stainless steel, it is crucial to maintain the integrity of stainless steel by changing out all the tools (grinders, wires, brushes, etc.) when switching between materials. This practice prevents remaining carbon steel particles from embedding into the stainless steel, which can cause it to rust. This is important because any rust or corrosion in the system can lead to performance issues and potentially costly repairs. American Wheatley sends stainless steel tanks out for bead blasting—a surface treatment that eliminates contaminants and gives the tank a smoother aesthetic. This ensures that the stainless steel composition will remain unblemished.

Partner with American Wheatley

Both carbon steel and stainless steel are great options for your HVAC system. However, your best choice depends on your specific system’s needs and performance goals. If you need assistance figuring out where to start, American Wheatley is here to help.

Call us at (918) 317-0401, and our knowledgeable customer service team will guide you in making the most beneficial and efficient choice for your HVAC system.