Unlocking the Flow: A Guide to Hydronics HVAC Valves

What Are Valves?

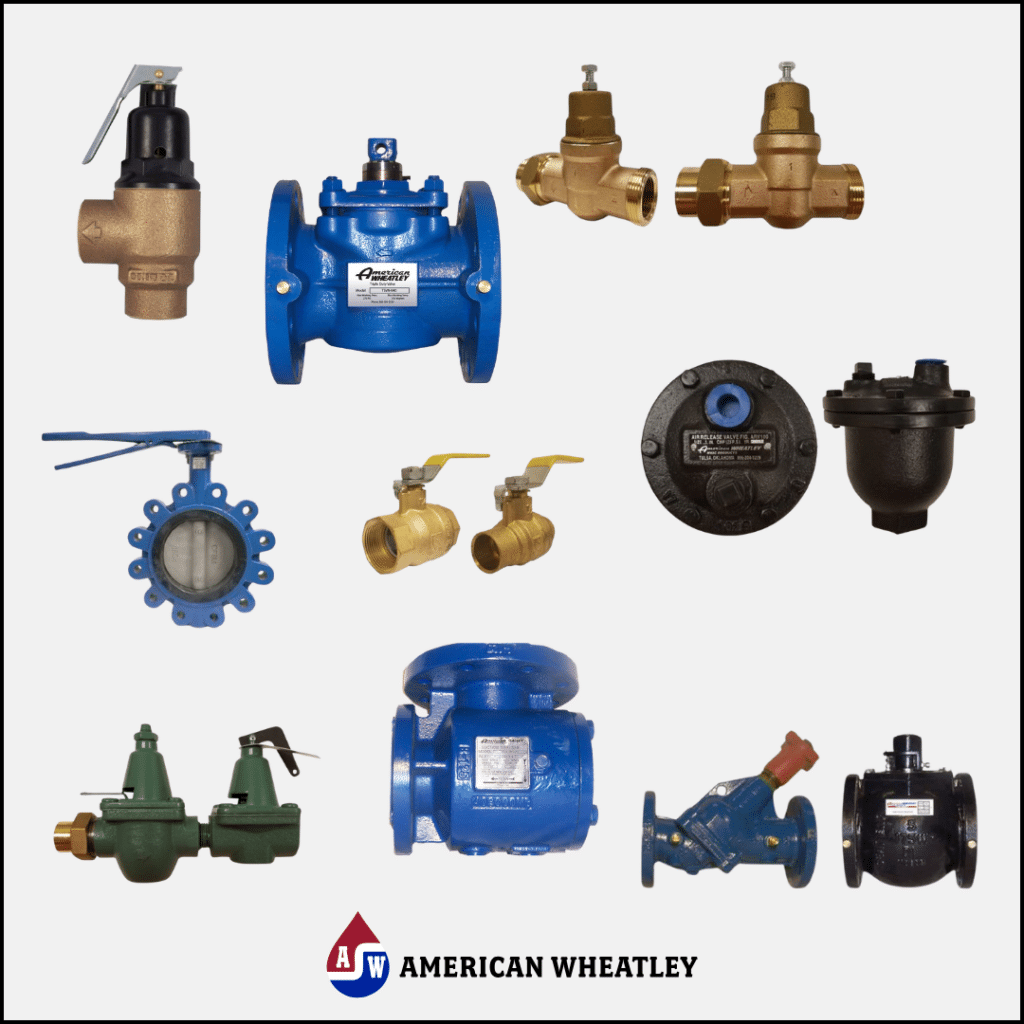

Valves are essential components in many industries, regulating flow and controlling the direction of fluids or gases. Understanding the different types of valves and their specific applications is crucial for efficient system operation and can help you make informed decisions for your particular systems. American Wheatley provides an in-depth overview of the different types of valves to help you make the best choice for your needs.

What Industries use Valves?

Some of the industries that extensively use valves include the power industry, water works, offshore industry, wastewater management, oil and gas production, pipelines, commercial construction, building and construction, and pharmaceutical and food manufacturing.

Butterfly Valves:

Butterfly valves are versatile and cost-effective, making them ideal for applications where space and weight constraints are critical. American Wheatley stocks high-quality butterfly valves suitable for HVAC systems, water treatment plants, and some industrial processes.

Triple-Duty Valves:

Triple-duty valves serve as a single-valve solution for various functions, including balancing, throttling, and shutoff in hydronic systems. American Wheatley’s expertise lies in providing reliable triple-duty valves for heating and cooling applications.

Check Valves:

Check valves allow one-way flow and prevent backflow, making them essential in applications where fluid or gas reversal must be avoided. American Wheatley stocks durable check valves suitable for sewage systems, water distribution networks, and hydraulic systems.

Balancing Valves:

Balancing valves are vital for maintaining the proper flow rates in hydronic systems, ensuring an even distribution of heating or cooling. American Wheatley offers precision in balancing valves for HVAC and hydronic systems.

Air Release Valves:

Air release valves are essential for removing trapped air in pipelines and preventing airlocks. American Wheatley’s air release valves are designed to maintain system efficiency and prevent issues in water distribution networks.

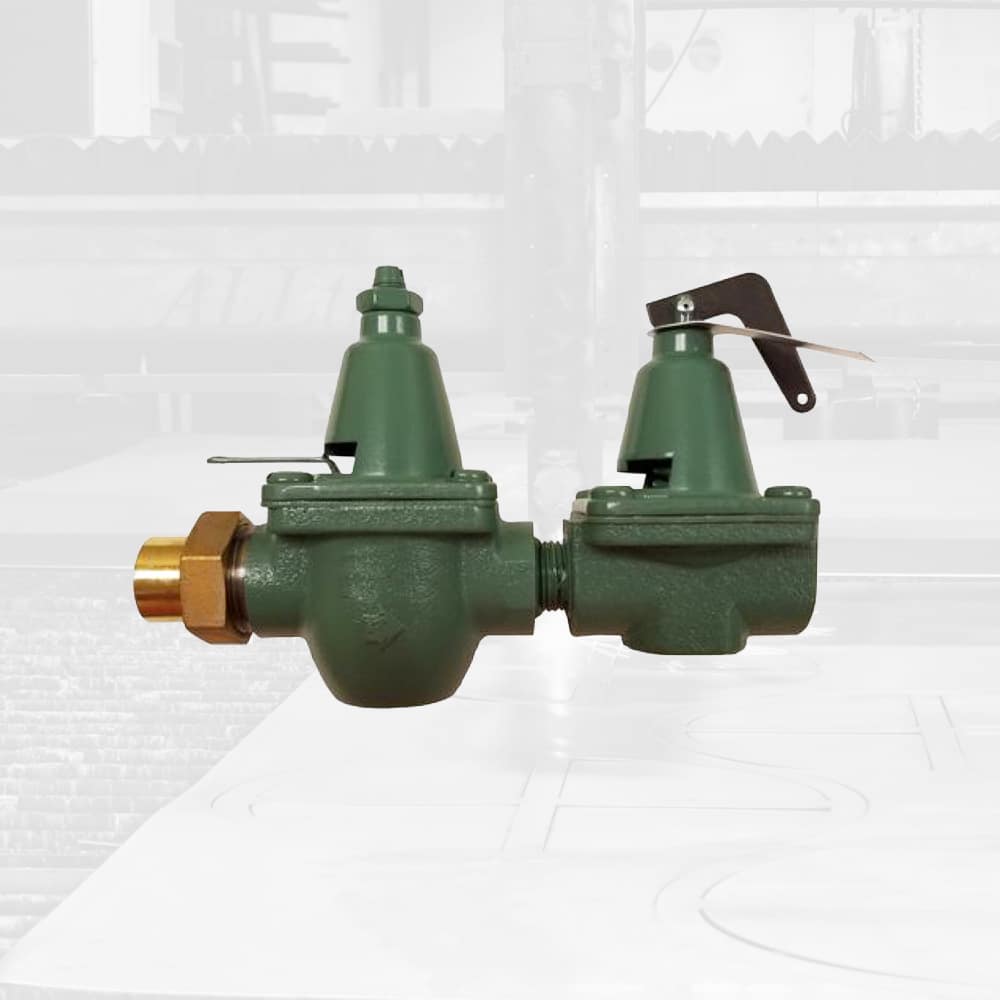

Relief Valves:

Relief valves protect equipment and systems from overpressure situations. American Wheatley stocks reliable relief valves for safety in industries such as oil refineries, chemical plants, and power generation facilities.

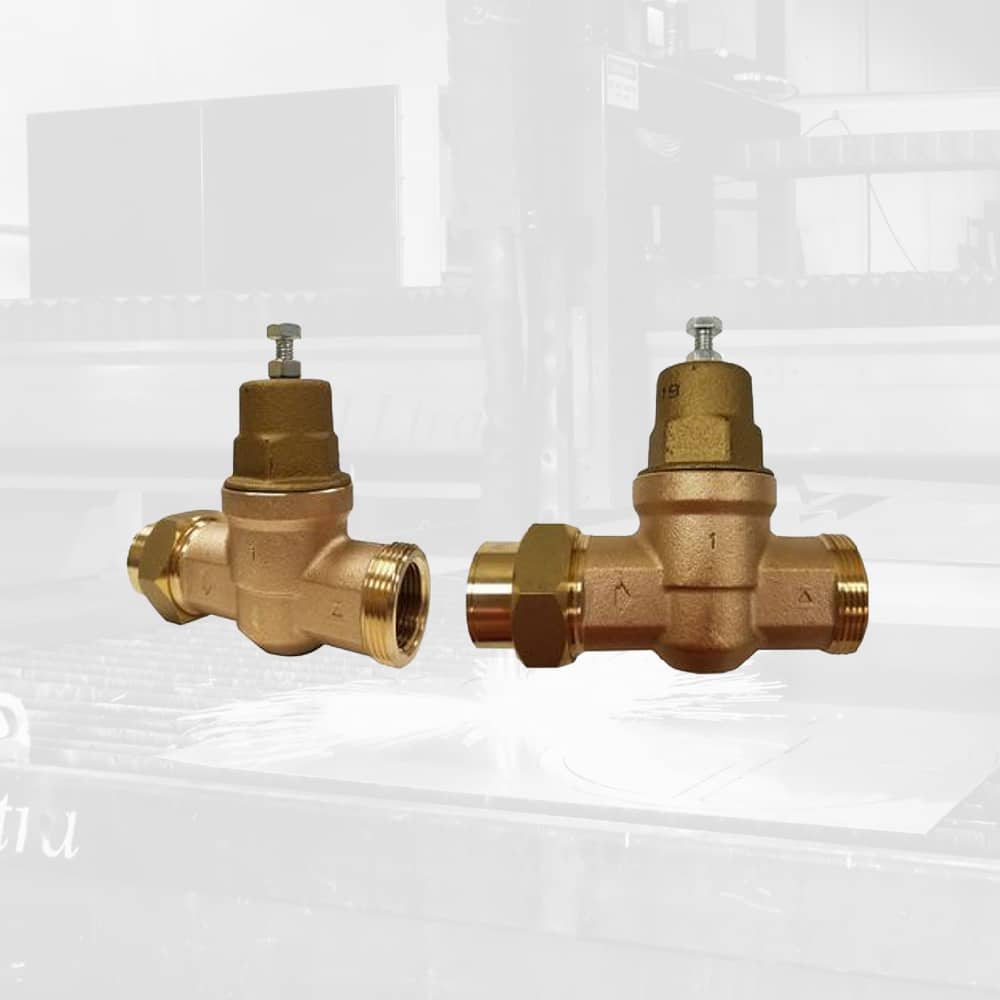

Water-Reducing Valves:

Water-reducing valves are designed to control and reduce water flow, making them suitable for plumbing systems and irrigation applications. American Wheatley provides efficient water-reducing valves for water conservation.

Dual Control Valves:

Dual control valves offer precise flow control and shutoff capabilities. They are commonly used in industrial processes and heating or cooling systems. American Wheatley’s dual control valves ensure reliable performance in critical applications.

Brass Ball Valves:

Brass ball valves are known for their durability and versatility. American Wheatley stocks high-quality brass ball valves suitable for various applications, including HVAC systems, water treatment, and industrial processes.

Key Terms

Hydronic Zone Valves: Precision in Control

Hydronic zone valves play a crucial role in segmenting a hydronic heating or cooling system. By dividing the system into zones, these valves allow for individual control of different areas, making it possible to regulate water flow based on specific needs. This is particularly beneficial in larger buildings where different rooms or areas may have varying heating or cooling demands. These valves facilitate a process where each zone receives the exact amount of heating or cooling required, leading to a more efficient and cost-effective system.

Pressure Drop and System Efficiency

Understanding pressure drop is key in hydronic systems. Hydronic valves, especially those that are pressure-dependent, are designed to handle changes in pressure within the system. A well-designed valve ensures that even with a pressure drop, the system operates efficiently. The pressure drop across a valve can impact how effectively it regulates the flow of water. Maintaining a balanced pressure drop is essential for the longevity and effectiveness of the system.

Regulating Water Flow for Optimal Performance

The primary function of hydronic valves is to regulate water flow. This regulation is crucial for maintaining the desired temperatures in different parts of a building. By controlling the amount of hot or cold water that flows through the system, these valves ensure that each zone receives the appropriate level of heating or cooling. This regulation process is integral to creating a balanced system that responds dynamically to the changing demands of the occupied space.

The Importance of Hydronic Components

Hydronic components, including valves, are the building blocks of any hydronic system. These components must be carefully selected and installed to ensure the system’s overall efficiency and reliability. The availability of high-quality components is crucial for building a system that meets the required heating or cooling conditions. Additionally, the ease of making adjustments to these components can significantly affect the system’s performance and maintenance requirements.

Adjustments and Maintenance: Keeping Systems at Peak Performance

Regular adjustments and maintenance of hydronic valves are essential for sustaining an efficient system. Over time, the demands on a hydronic system may change, and the valves must be adjusted accordingly to continue meeting these needs. Easy-to-adjust valves simplify this process, allowing for quick modifications that can significantly impact the system’s overall effectiveness.

Summary

Hydronic valves, whether they’re regulating flow, responding to pressure changes, or ensuring a balanced system, are indispensable components of hydronic heating and cooling systems. Their ability to meet the specific demands of different zones, adjust to varying conditions, and maintain system efficiency underlines their importance in HVAC design. The availability of quality hydronic components and the ease of making necessary adjustments add to the appeal of these systems, making them a preferred choice for effective temperature regulation in buildings.

Frequently Asked Questions

What valves are in a hydronic system?

In a hydronic heating or cooling system, several types of valves are used to control water flow and maintain system efficiency. These valves include:

Zone Valves: Used to control the flow of water to different zones or areas of a building for heating or cooling.

Balancing Valves: Essential for adjusting the flow rate in different circuits of the system to ensure even distribution of heat or cooling.

Shutoff Valves: Allow for the isolation of parts of the system for maintenance or in case of a leak.

Check Valves: Prevent backflow of water, ensuring that it only moves in the intended direction through the system.

Pressure Reducing Valves: Regulate the pressure within the system to prevent damage to pipes and components.

Diverter Valves: Direct the flow of water between heating and hot water circuits in some systems.

Relief Valves: Safety valves that release water if the pressure or temperature exceeds safe levels.

Each valve plays a crucial role in the system’s overall operation, efficiency, and safety.

What is hydronics in HVAC?

Hydronics in HVAC refers to systems that use water as a medium for heating and cooling distribution throughout a building. Unlike forced-air systems that use air to transport heat, hydronic systems circulate hot or cold water through pipes to radiators, underfloor heating tubes, or air handlers. This method is known for its efficiency, ability to maintain consistent temperatures, and flexibility in zoning. Hydronic systems can be heated with various sources, including boilers, solar water heaters, and heat pumps, and can also be integrated with cooling systems to provide comprehensive climate control.

What is a hydronic zone valve?

A hydronic zone valve is a specific type of valve used in hydronic heating and cooling systems to control the flow of water to different zones or areas within a building. Each valve is electrically controlled and can open or close to allow hot or cold water to flow into a particular zone, such as a room or group of rooms. This zoning capability enables individual temperature control in different areas, improving comfort and system efficiency by only heating or cooling spaces as needed.

What is a hydronic balancing valve?

A hydronic balancing valve is designed to adjust the flow rate in the pipes of a hydronic heating or cooling system to ensure even distribution of heat or chilled water throughout the system. Proper balancing is crucial for the efficiency and performance of a hydronic system, as it ensures that all areas receive the appropriate amount of heating or cooling. These valves are adjusted during system commissioning and may be readjusted if the system layout changes or if imbalances are detected during operation.

What is a pressure relief valve in a hydronic system?

A pressure relief valve in a hydronic system is a safety device designed to protect the system from excessive pressure. If the system pressure exceeds a preset limit, the valve opens to release water and lower the pressure, preventing potential damage to pipes, radiators, and other components. This valve is crucial for maintaining the safety and integrity of the system, especially in closed-loop systems where expanding water can increase pressure.

What is the purpose of a diverter valve in a hydronic system?

A diverter valve in a hydronic system directs the flow of water between different paths based on the system’s needs. For instance, in a combination boiler system, the diverter valve might switch between sending hot water to radiators for heating and to taps for domestic hot water use. It ensures that the system efficiently meets the demand for heating and hot water without simultaneously operating both circuits, optimizing energy use and system performance.

How do check valves function in hydronic heating systems?

Check valves in hydronic heating systems allow water to flow in one direction while preventing backflow. They are crucial for maintaining the correct flow direction through the system, especially in complex layouts with multiple loops or branches. By preventing backflow, check valves help maintain consistent heating, reduce the risk of thermal mixing (hot water mixing with cold), and ensure that the system operates as designed.

Why are shutoff valves important in hydronic systems?

Shutoff valves are critical components in any hydronic system for maintenance, repair, and emergency purposes. They allow for the isolation of different parts of the system without the need to drain the entire system. This capability is essential for servicing individual components such as radiators, pumps, or valves without affecting the rest of the system, ensuring minimal downtime and disruption.

Can balancing valves improve energy efficiency in hydronic systems?

Balancing valves can significantly improve energy efficiency in hydronic systems. By ensuring that water flow is evenly distributed according to the design requirements of each zone or circuit, balancing valves eliminate over-pumping and under-pumping scenarios. This precise control reduces the energy consumption of pumps and boilers, as the system doesn’t need to work harder than necessary to compensate for imbalances. Properly balanced systems also enhance comfort by evenly distributing heating or cooling throughout the building.

HVAC & Valve Experts

About American Wheatley

Our expertise can be invaluable when selecting the suitable valve for your application. We understand the nuances of each valve type we stock, and our team can guide valve selection, installation, and maintenance. Our team prioritizes safety, efficiency, and reliability, ensuring your systems operate seamlessly with our valves. We also provide a curated selection of high-quality valves designed for diverse applications. By partnering with us, you gain access to a wealth of knowledge and expertise, ensuring you make the best choices for valve-related challenges in your industry. Whether you need precise flow control, on/off shutoff, or pressure relief, American Wheatley has the solutions and insights you need for your valve requirements.