Four Hydronic Specialty Products for More Efficient Heating & Cooling

American Wheatley is consistently recognized for exceptional hydronic specialty products.

Today’s businesses depend on high-quality and reliable heating, ventilation, and air conditioning systems tailored to their specific needs. For instance, if you desire greater energy efficiency or work with high-heat industrial processes, you may need something more powerful than the conventional forced air system.

A hydronic system, also known as a hydronic heating system, is a method of heating or cooling a building using water as the medium to transfer thermal energy. In a hydronic system, hot water or chilled water is circulated through a network of pipes, radiators, baseboard heaters, or other heat exchange devices to distribute heat or cool air throughout space.

As long-standing experts in the HVAC industry, American Wheatley is consistently recognized for our exceptional hydronic specialty products. Discover four of our innovations that have gained acclaim in the field.

Air Separators:

Air separators play a crucial role in hydronic systems by removing air and other gases, which can cause operational issues and decrease system efficiency.

American Wheatley’s air separators eliminate air from the system, ensuring optimal heat transfer and preventing air-related problems. These separators feature robust construction, innovative design, and efficient air removal capabilities. Hydronic systems can operate smoothly by utilizing American Wheatley’s air separators, enhancing overall performance and reducing maintenance requirements.

Expansion Tanks:

Expansion tanks are critical components of hydronic systems designed to accommodate the expansion and contraction of water as it heats and cools.

American Wheatley offers a range of expansion tanks that ensure system efficiency and longevity. These tanks are constructed with durable materials, such as carbon steel or stainless steel, and come in various sizes to suit different system capacities. American Wheatley’s expansion tanks are known for their exceptional performance, reliability, and easy maintenance, making them a preferred choice for hydronic applications.

Hydronic Specialties:

Hydronic systems offer an array of benefits—but they can be complicated to install and/or service if you are not working with the right products.

American Wheatley provides an array of other hydronic specialties to solve for specific challenges your commercial property might face. These include air vents, magnetic dirt separators, boiler feed systems, and heat exchangers. Each specialty product is designed to focus on quality, functionality, and ease of use. American Wheatley’s hydronic specialties contribute to hydronic systems’ overall efficiency, performance, and longevity, ensuring reliable operation and customer satisfaction.

Triple-Duty Valves:

Triple-duty valves combine the functionalities of a check valve, balancing valve, and shut-off valve in a single unit. These valves streamline installation, reduce space requirements, and simplify system maintenance.

American Wheatley offers a range of precision-engineered triple-duty valves for hydronic systems, and these valves enable efficient flow control, provide reliable shut-off capabilities, and promote hydraulic balance within the system.

By choosing American Wheatley’s products, HVAC professionals and system designers can rely on top-notch performance, durability, and ease of installation.

For more information about American Wheatley’s products, click below.

Having an air separator in your HVAC system greatly affects the system’s overall performance, especially in a chilled-water system. While air elimination is important in any ventilation setting, it is more important in the chilled-water system than in a hot-water system because the cold-water unit can hold more air inside the tank.

Air separation is a common term when discussing HVAC equipment. There is a wide variety of Air Separators, and there are several uses depending on your needs.

While Dissolved Air Flotation (DAF) is necessary even in a ventilation system with manual vents, it is still very important to consider having an air separator because no hydronic system is airtight. Otherwise, the constant air/water mixture being pumped will dramatically decrease heat transfer efficiencies. A proper air separator also decreases oxygen exposure which is important because oxygen causes a large amount of corrosion that will contaminate the system.

What are the HVAC Air Separator options?

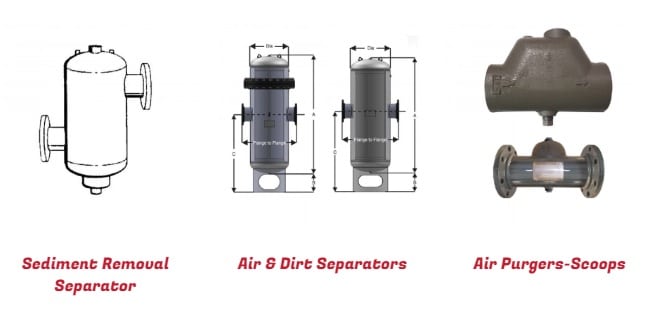

Some options for air separation units are:

- Tangential Air Separators

- In-Line Air Separators

- Sediment-Removal Separators

- Air & Dirt Separators

- Air Purgers or Air Scoops

Along with the outlined air separators, there are also options available for these units such as:

- Strainer

- Less Strainer

- MG – Magnetic Options

If you are interested in a more customized solution, please reach out to us regarding custom fabrication.

How do these Air Separators work?

Each air separator has its own method for air elimination. Below, we describe the outlined options listed above.

Tangential Air Separators

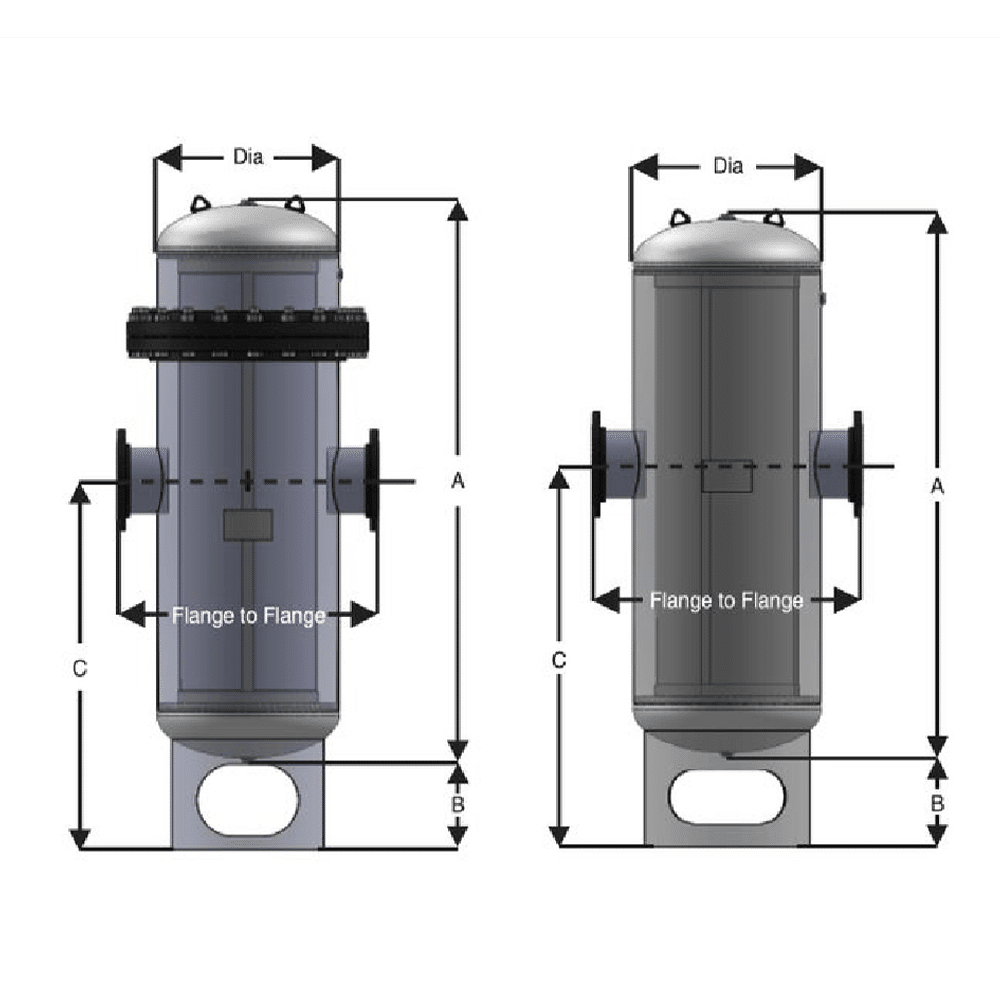

The Tangential Air Separator design provides air-free fluid flow which protects against damage and system noise. This unit features grooved or flanged inlet and outlet connections. The tangential design results in a smaller unit. There are higher-working pressures available for this air separator.

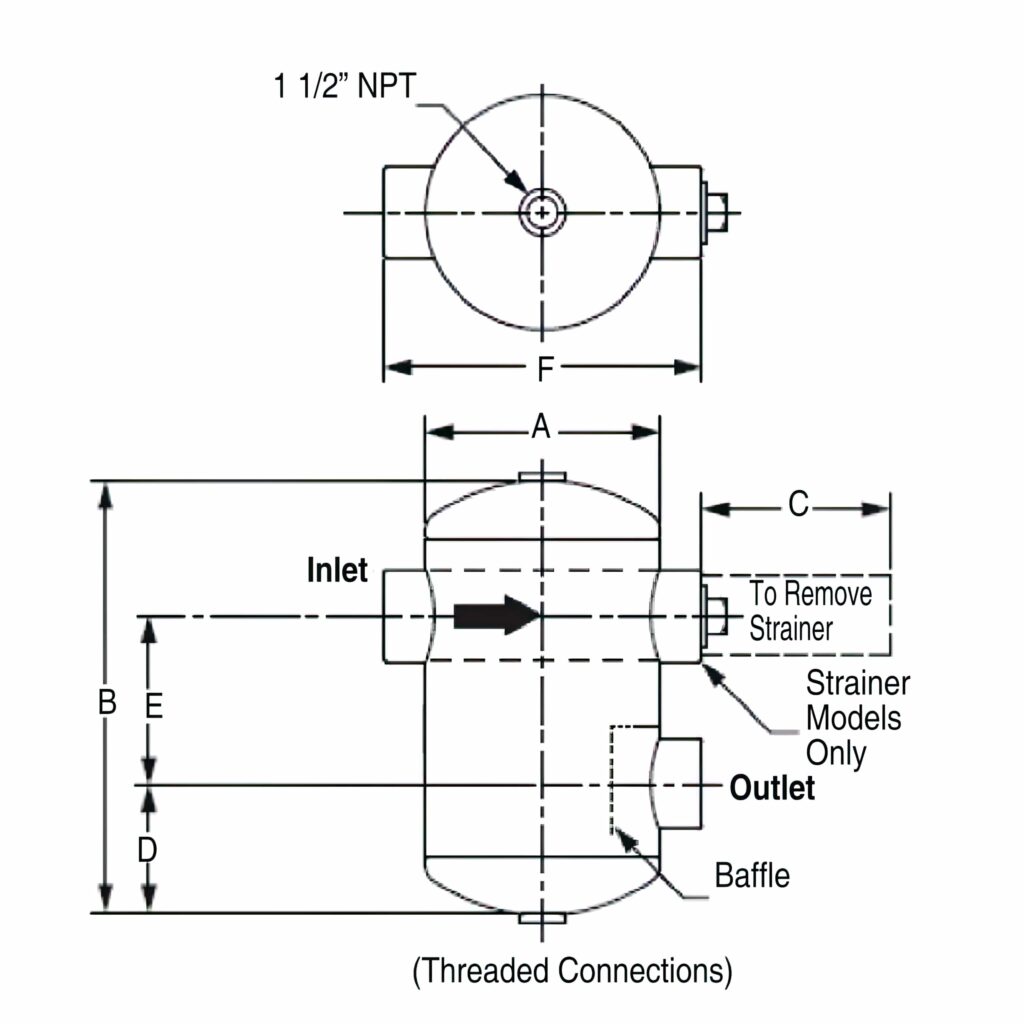

In-line Air Separators

Our In-line Air Separators series offers a lower-cost alternative for air separation in hydronic heating and cooling systems. The IAS/IASS series becomes a point of lower system velocity by changing the direction of flow through the device.

This lower velocity along with the change in direction allows air molecules to separate from water. Once the separation occurs, the air rises within the inline air separator. Then, it is discharged through the vent opening at the top of the vessel. This will go to either the atmosphere or an expansion tank.

Sediment Removal Separators

The Sediment Removal Separator (SRS) is a centrifugal-type sediment removal. While the design is similar to the TAS Series Air Separator, the SRS also offers the advantage of solids removal.

The tangential design allows for sediment removal through the vortex action, which forces suspended sediment to the outside of the vessel and into the bottom sump. You can then easily remove the sediment. The tangential action also creates a vortex that forces entrained air into the center and removes it through the top opening. It is then released into the atmosphere or sent to an expansion tank.

Air & Dirt Separators

The High-Velocity and STAD Standard Velocity Coalescing Air & Dirt Separator is intended for use on commercial HVAC, institutional, and industrial applications to remove entrained air and particulate from system water. This is accomplished by the use of a High-Performance saddle ring coalescing assembly internal to the separator.

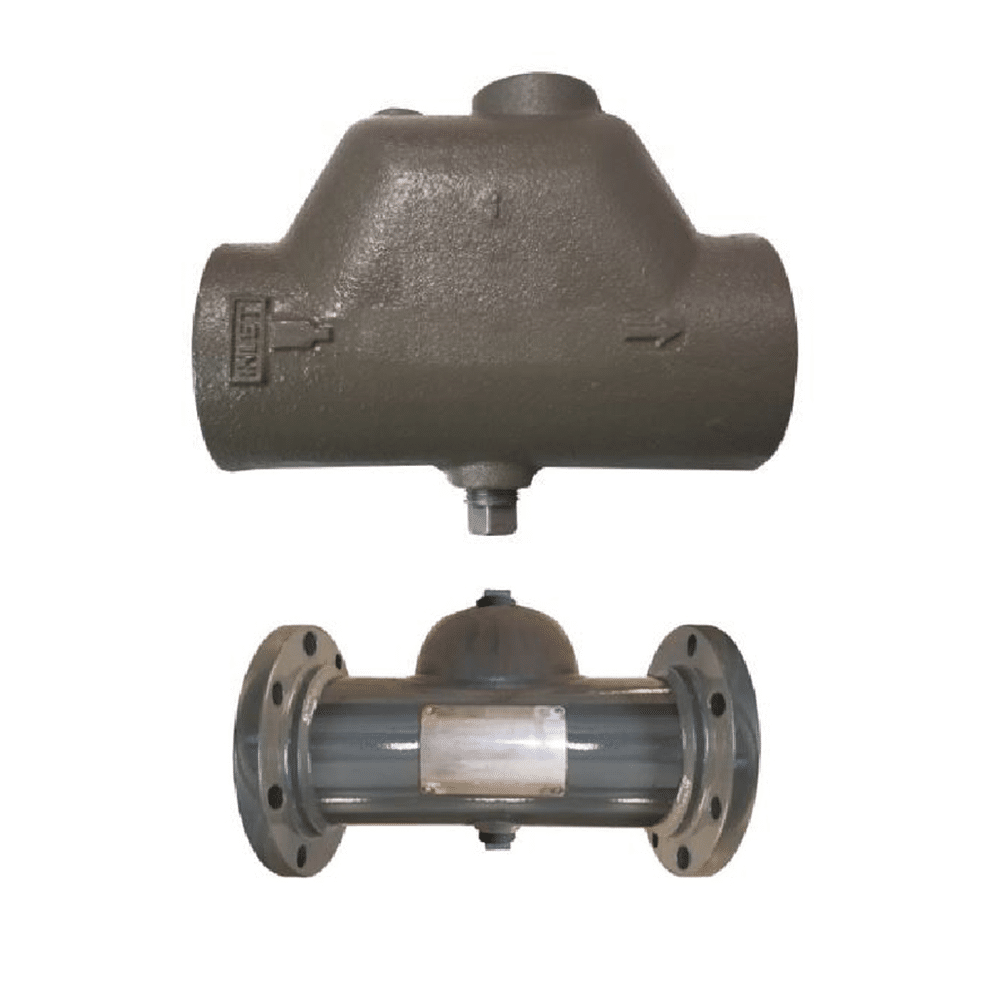

Air Purgers (Air Scoops)

The Air Purger or Air Scoop operates on the premise that air rises in the piping and then into the unit. It is directed to the top opening and out of the system through an air vent or to an expansion tank. Since the proper operation of this type of air separator is also dependent on velocity, sizing this type of air separator is a function of proper flow rate. This type of air separation is best suited for residential and light commercial applications.

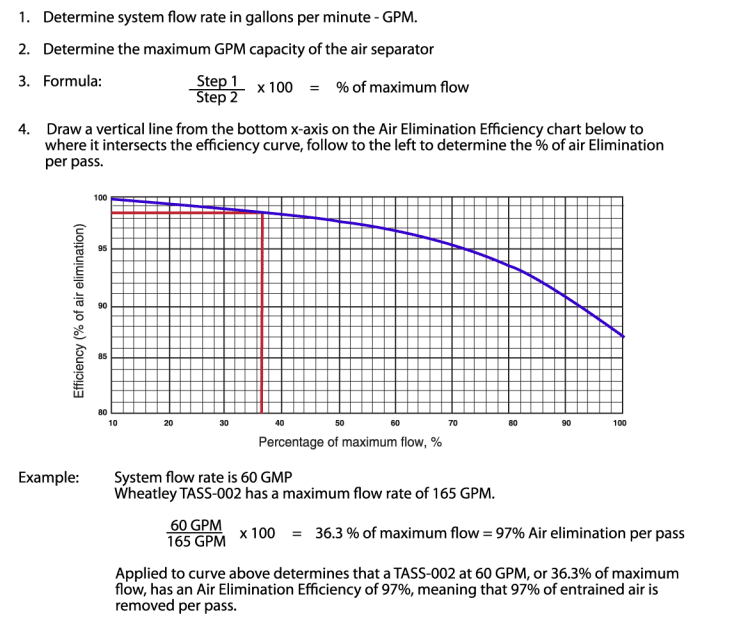

How to determine Air Elimination Efficiency

Need Assistance?

There are plenty of model options available at American Wheatley HVAC. If you are uncertain which of these models will work best for you or need more customization, please reach out to us. We are eager and ready to help you find the right solution for your needs!

* Our American Wheatley HVAC Brand Air Separators are constructed and stamped according to ASME Section VIII Boiler and Pressure Vessel Code requirements and National Board registered.