Why Quality in HVAC Fabrication and Accessories Matters

In the realm of HVAC fabrication and air receiver solutions, there exists a critical choice that every industry professional must make: prioritizing price or investing in quality. While budget constraints may tempt us to opt for more affordable options, it is imperative to recognize the long-term benefits of choosing superior-quality products. American Wheatley, renowned for its meticulously fabricated tanks and top-notch accessories and hardware products, embodies an unparalleled commitment to excellence in the industry and dives into the importance of investing in high-quality HVAC fabricated products and accessories.

The Craftsmanship that Sets American Wheatley Apart

American Wheatley has been a beacon of quality in the HVAC industry for decades. Our fabrication process is nothing short of an art form where precision and expertise converge to create products built to last. Each tank and accessory undergoes rigorous quality checks to meet and exceed industry standards. This unwavering dedication to craftsmanship translates into HVAC solutions that are not only reliable but also capable of withstanding the test of time.

Superior Materials for Superior Performance

One of the cornerstones of American Wheatley’s success lies in its commitment to using only the highest quality materials. Whether stainless steel for tanks or accessories, every component is carefully selected to ensure optimal performance. This meticulous material selection process translates into products resistant to corrosion, capable of withstanding extreme temperatures and designed to maintain structural integrity under the harshest conditions.

Reliability that Transcends Expectations

In the world of HVAC, downtime can be a costly affair. Choosing products prone to frequent breakdowns or premature wear and tear is a risk that no industry professional can afford. American Wheatley’s tanks and accessories are engineered with reliability at the forefront. By investing in American Wheatley, you’re not just purchasing a product; you’re securing a solution that will operate seamlessly, day in and day out, providing peace of mind for years to come.

Uncompromising Safety Standards

Safety is non-negotiable at American Wheatley. Poorly fabricated tanks or subpar accessories can lead to catastrophic failures, endangering personnel and equipment. American Wheatley’s commitment to safety is woven into every product we offer – from tanks to accessories. Our tanks are designed to meet and exceed industry safety standards. This ensures that your quality HVAC system operates safely, protecting your investment and the well-being of those who rely on it.

Cost-Efficiency in the Long Run

While it’s true that quality products may come with a higher upfront cost, the long-term savings they offer are undeniable. American Wheatley’s tanks and accessories are engineered for longevity, reducing the need for frequent replacements or repairs. This translates into substantial cost savings over the lifespan of the HVAC system. Moreover, our products often outperform cheaper alternatives regarding energy efficiency, further bolstering your bottom line.

Elevating Your HVAC System with American Wheatley

Ultimately, deciding to prioritize quality over price is an investment in the future success of your operation. With American Wheatley, you’re not just making a purchase; you’re making a statement about your dedication to excellence in HVAC solutions. Elevate your HVAC system with American Wheatley and experience the unparalleled difference that quality in HVAC makes.

Step-by-Step Guide to Safely Servicing an HVAC Tank

As the crisp autumn air settles in and jack-o’-lanterns illuminate the night, the season brings bone-chilling fun. Ensure these are the only chills that your employees and customers experience by properly servicing your HVAC system before the weather changes.

Here at American Wheatley, we understand the importance of safety and will share a step-by-step guide and essential safety tips to follow when servicing an HVAC tank.

Step 1: Prepare Your Work Area

Before beginning any HVAC tank service, creating a safe and organized work environment is crucial. Follow these steps:

- Clear the area: Remove any debris, clutter, or obstacles that may impede your movement around the tank.

- Adequate lighting: Avoid things that go “bump in the night”—ensure your work area is well-lit to avoid accidents or errors caused by poor visibility.

- Ventilation: Confirm that the work area is properly ventilated to prevent the accumulation of potentially harmful gases or fumes.

Step 2: Wear Appropriate Personal Protective Equipment (PPE)

Protecting yourself is key when working with HVAC tanks. Wear the following PPE to minimize the risk of injury:

- Safety goggles: Protect your eyes from debris, chemicals, or other hazards.

- Respiratory protection: Depending on the specific task and the potential for exposure to harmful gases or particulates, wear appropriate respiratory protection such as a mask or respirator.

- Gloves: Use gloves suitable for the job. For example, choose chemical-resistant or insulated gloves when working with electrical components.

- Protective clothing: Wear clothing that covers your skin and is resistant to chemicals, sparks, or other potential hazards.

Step 3: Follow Proper Lockout/Tagout Procedures

Lockout/tagout procedures are essential for ensuring the safety of both the technician and others who may come into contact with the equipment. Follow these guidelines:

- Shut off power sources: Identify and disconnect all power sources from the HVAC tank before beginning any service or maintenance work.

- Lock and tag the equipment: Use lockout devices and tags to prevent the accidental re-energization of the equipment. Mark the locked-out equipment with warning signs.

Step 4: Handle Hazardous Substances with Care

HVAC tank servicing may involve dealing with hazardous substances, such as refrigerants. Here are some precautions to take:

- Chemical storage and handling: Store chemicals in designated areas, following the manufacturer’s instructions. Use appropriate containers and ensure proper labeling.

- Spill response plan: Establish a spill response plan in case of accidental spills or leaks. Have absorbent materials and neutralizing agents readily available.

- Proper disposal: Dispose of hazardous materials and waste in accordance with local regulations. Do not pour chemicals down drains or into the environment.

Step 5: Follow Routine Maintenance

Maintain equipment and tools by routine regular maintenance, which is crucial for safe operation. Follow these maintenance practices:

- Regular inspections: Conduct routine inspections to identify and address any signs of wear, damage, or malfunction in your equipment.

- Proper tool usage: Use tools and equipment according to their intended purpose. Inspect tools for damage before use and replace any worn or defective tools.

Following these step-by-step guidelines and adhering to safety precautions, servicing an HVAC tank doesn’t have to be a source of fear or apprehension. Ensure a safe working environment, wear appropriate PPE, follow lockout/tagout procedures, handle hazardous substances carefully, and maintain your equipment and tools.

Above all, remember that safety is paramount in the HVAC manufacturing industry. If you have any questions, reach out to the trusted experts at American Wheatley or click below to view our products.

Three Ways Labor Day Continues to Improve HVAC Manufacturing

American labor is the backbone of our nation. Over the years, American workers have helped raise our standard of living while growing the world’s largest economy.

The Origins and Evolution of Labor Day

American labor is the backbone of our nation. Over the years, American workers have helped raise our standard of living while growing the world’s largest economy, which currently stands at $23.3 trillion GDP. However, it has not been an easy road. Workers braved long hours and dangerous conditions, banding together to fight for better wages and safe workplaces. In recognition, we now pay tribute to these hard-working men and women with an annual Labor Day celebration.

Labor Day originated in the late 19th century due to the labor movement’s efforts to advocate for better working conditions and workers’ rights. The first Labor Day was celebrated on September 5, 1882, in New York City, with a parade organized by the Central Labor Union. It became a national holiday in 1894 when President Grover Cleveland signed a law designating the first Monday in September as Labor Day.

As we at American Wheatly commemorate 141 years of Labor Day, let us reflect on the significant impact this holiday continues to have on the manufacturing of HVAC fabrication products today.

Workers’ Rights

Labor Day is significant for workers as it symbolizes their achievements and progress in securing workers’ rights. It serves as a tribute to the contributions and resilience of the American workforce throughout history. This celebration highlights the importance of fair wages and reasonable working hours.

At American Wheatley, we prioritize competitive wages and comprehensive benefits by consistently evaluating market conditions. Staying informed about industry trends, economic fluctuations, and the cost of living helps us put together a compensation package that attracts and retains top talent.

Workplace Safety and Standards

The labor movement’s advocacy for safer working conditions directly impacted the HVAC manufacturing industry. Labor Day has raised awareness about the importance of workplace safety and led to the establishment of safety regulations, standards, and inspections that safeguard HVAC workers’ well-being.

American Wheatley prioritizes our team’s safety above anything else. Some of the regulations we adhere to include:

- Personal Protective Equipment (PPE): Employees in our facilities are required to wear appropriate PPE, such as safety goggles, gloves, protective clothing, and respiratory masks, to prevent injuries and exposure to hazardous materials.

- Hazardous Material Handling: We impose strict guidelines for the handling, storage, and disposal of hazardous materials used in HVAC manufacturing, including refrigerants, chemicals, and cleaning agents, to minimize the risk of accidents.

- Electrical Safety: Regulations pertaining to electrical safety are enforced to protect workers from electrical hazards, including electrical shock and fires, by ensuring proper installation, maintenance, and regular inspection of electrical equipment.

- Fire Safety: Our manufacturing facilities have fire safety protocols, including fire extinguisher placement, evacuation plans, and fire suppression systems, to promptly respond to and contain fires.

Training and Education Initiatives

In recognition of Labor Day, various organizations have supported training and education programs in the HVAC industry. These initiatives have helped enhance the skills and knowledge of workers, ensuring a highly trained and competent workforce in the manufacturing sector.

While we strive for excellence in our work, American Wheatley focuses on providing our employees with meaningful personal and professional development opportunities. As we help our customers grow their HVAC businesses, we help our employees grow in the process.

This Labor Day, we extend our deepest appreciation for our teams’ extraordinary commitment, passion, and unwavering dedication. They are the heart and soul of our organization, and we are proud to have them as part of the American Wheatley team. Happy Labor Day!

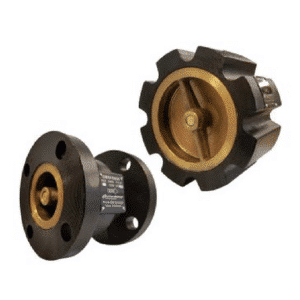

American Wheatley HVAC Check Valves are engineered for silent operation and even little head loss. The Wafer Style Non-Slam Check Valve will automatically prevent your system from experiencing a back-flow, when your system is desired to flow in one direction only and keep the flow from moving in the opposite direction. The disc in this valve will open automatically, as soon as the pump begins the downstream flow, providing the amount of pressure required to move in the forward direction. The disc is also going to close automatically, when the pump has stopped and the flow has started to slow down – closing before the reversal of the flow. This ensures that the reversal of the flow was positively shut off.

HVAC Check Valves Available:

- Wafer Style Non Slam

- Flanged Globe Style Non Slam

- Dual Disc Non Slam

- Threaded Silent

Wafer Style Non Slam Check Valve

The Wafer Style Non Slam Check Valve is designed for silent operation, closing the check valve before the reversal of the flow, and even for low head loss, decreasing the amount of fluid pressure. This check valve will completely eliminate your water hammer, reduce your pressure loss, and provide maximum efficiency. Our Wafer Style Check Valve comes engineered with a compact flange design. It’s activated at a low psi of ¼ through ½, and the sizes we have available are 2 inch through 16 inch. The 2 inch through the 6 inch are Dual Rated at 125 and 250 psi.

Flanged Globe Style Non Slam Check Valve

The Flanged Globe Style Non Slam Check Valve is designed for silent operation and low head loss, allowing for the check valve to close before the reversal of the flow and decreasing the amount of pressure. This valve will get rid of your water hammer, providing little pressure loss, and maximum efficiency. This Check Valve comes with a compact design flange face to flange face, providing the shortest feasible face to face dimensions. This valve is activated at a low psi of ¼ through ½. The sizes we have available for this valve are 2 inch through 16 inch.

Flanged Dual Disc Non Slam Check Valve

The Flanged Dual Disc Non Slam Check Valve has a painted exterior and is available in sizes ranging through 2 and 16 inches. They have ductile iron bodies, with flanged ends. This check valve is designed with a compact wafer design and comes with little head loss. It is engineered with a stabilized disc and stop pins, and non-slam closing characteristics. This valve allows for a lift and pivot disc action, and has drop light seating at low and high pressures.

Threaded Silent Check Valve

The Threaded Silent Check Valve is available in sizes ranging from ½ inch through 2 inches. These check valves are designed with bronze bodies and threaded ends. They provide silent operation and allow for a fast closure, in order to prevent check valve slam water hammer.

For more information regarding the American Wheatley HVAC Valves we have available, visit our HVAC Valves product page. Please don’t hesitate to contact us, anytime, for any question you may have or for more information regarding American Wheatley HVAC Check Valves.

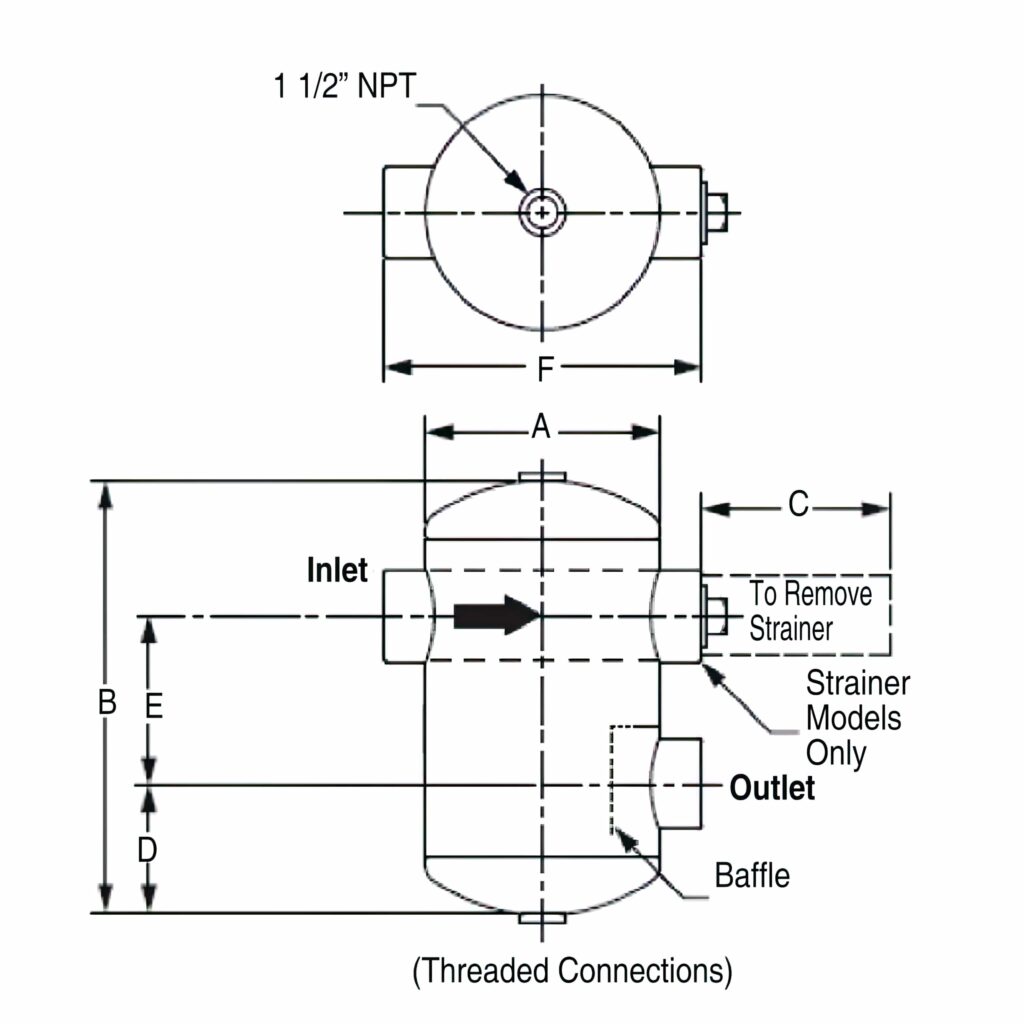

Having an air separator in your HVAC system greatly affects the system’s overall performance, especially in a chilled-water system. While air elimination is important in any ventilation setting, it is more important in the chilled-water system than in a hot-water system because the cold-water unit can hold more air inside the tank.

Air separation is a common term when discussing HVAC equipment. There is a wide variety of Air Separators, and there are several uses depending on your needs.

While Dissolved Air Flotation (DAF) is necessary even in a ventilation system with manual vents, it is still very important to consider having an air separator because no hydronic system is airtight. Otherwise, the constant air/water mixture being pumped will dramatically decrease heat transfer efficiencies. A proper air separator also decreases oxygen exposure which is important because oxygen causes a large amount of corrosion that will contaminate the system.

What are the HVAC Air Separator options?

Some options for air separation units are:

- Tangential Air Separators

- In-Line Air Separators

- Sediment-Removal Separators

- Air & Dirt Separators

- Air Purgers or Air Scoops

Along with the outlined air separators, there are also options available for these units such as:

- Strainer

- Less Strainer

- MG – Magnetic Options

If you are interested in a more customized solution, please reach out to us regarding custom fabrication.

How do these Air Separators work?

Each air separator has its own method for air elimination. Below, we describe the outlined options listed above.

Tangential Air Separators

The Tangential Air Separator design provides air-free fluid flow which protects against damage and system noise. This unit features grooved or flanged inlet and outlet connections. The tangential design results in a smaller unit. There are higher-working pressures available for this air separator.

In-line Air Separators

Our In-line Air Separators series offers a lower-cost alternative for air separation in hydronic heating and cooling systems. The IAS/IASS series becomes a point of lower system velocity by changing the direction of flow through the device.

This lower velocity along with the change in direction allows air molecules to separate from water. Once the separation occurs, the air rises within the inline air separator. Then, it is discharged through the vent opening at the top of the vessel. This will go to either the atmosphere or an expansion tank.

Sediment Removal Separators

The Sediment Removal Separator (SRS) is a centrifugal-type sediment removal. While the design is similar to the TAS Series Air Separator, the SRS also offers the advantage of solids removal.

The tangential design allows for sediment removal through the vortex action, which forces suspended sediment to the outside of the vessel and into the bottom sump. You can then easily remove the sediment. The tangential action also creates a vortex that forces entrained air into the center and removes it through the top opening. It is then released into the atmosphere or sent to an expansion tank.

Air & Dirt Separators

The High-Velocity and STAD Standard Velocity Coalescing Air & Dirt Separator is intended for use on commercial HVAC, institutional, and industrial applications to remove entrained air and particulate from system water. This is accomplished by the use of a High-Performance saddle ring coalescing assembly internal to the separator.

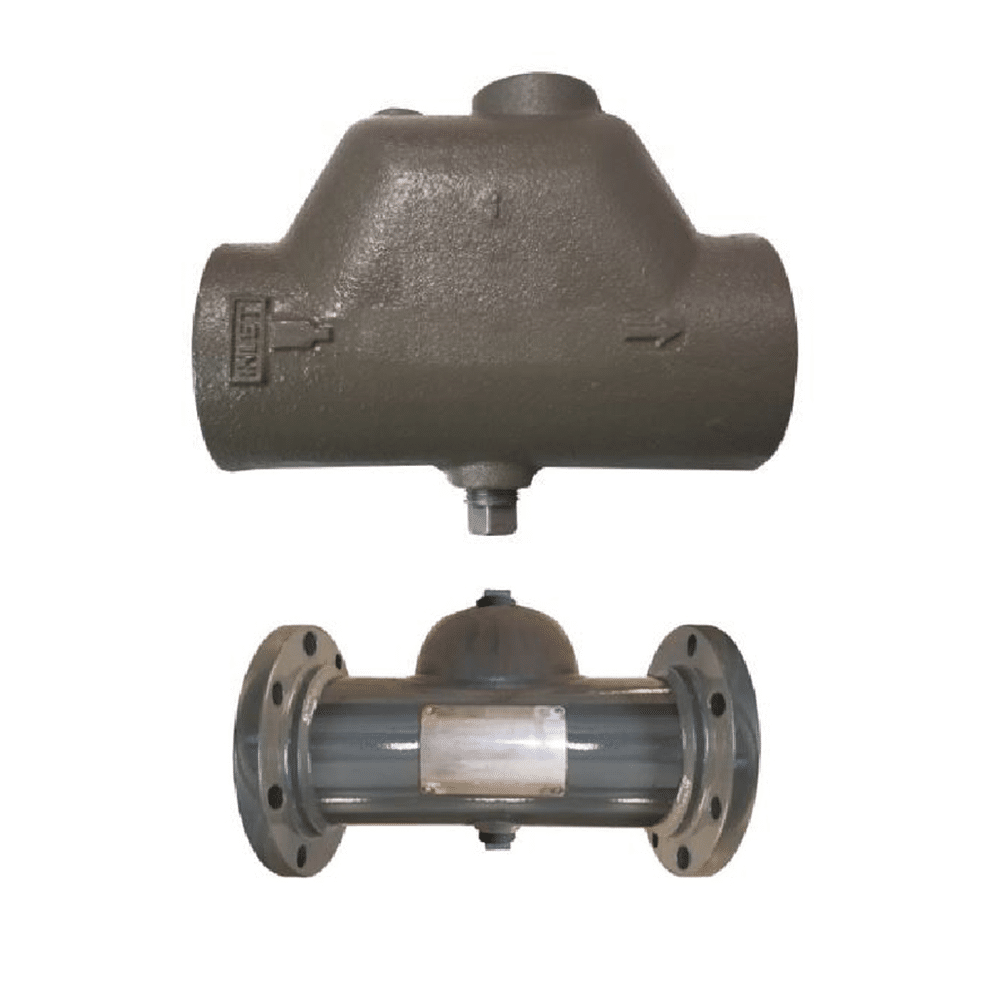

Air Purgers (Air Scoops)

The Air Purger or Air Scoop operates on the premise that air rises in the piping and then into the unit. It is directed to the top opening and out of the system through an air vent or to an expansion tank. Since the proper operation of this type of air separator is also dependent on velocity, sizing this type of air separator is a function of proper flow rate. This type of air separation is best suited for residential and light commercial applications.

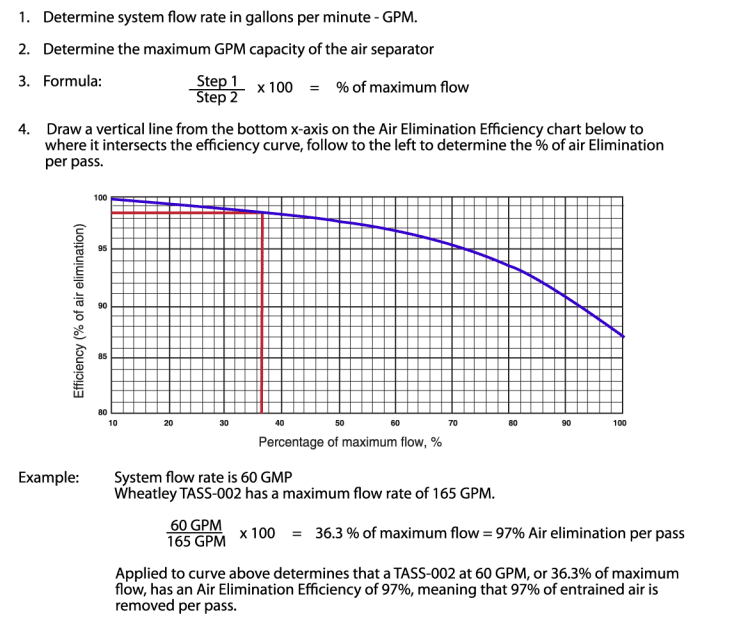

How to determine Air Elimination Efficiency

Need Assistance?

There are plenty of model options available at American Wheatley HVAC. If you are uncertain which of these models will work best for you or need more customization, please reach out to us. We are eager and ready to help you find the right solution for your needs!

* Our American Wheatley HVAC Brand Air Separators are constructed and stamped according to ASME Section VIII Boiler and Pressure Vessel Code requirements and National Board registered.

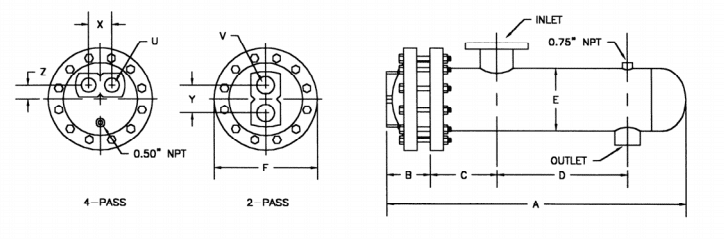

American Wheatley HVAC offers a full range of Shell & Tube and Plate & Frame heat exchangers available in sizes 4″ through 30″, manufactured in accordance with ASME Section VIII. We also offer a complete line of Plate & Frame Heat Exchangers. Whether you’re heating or cooling, these heat exchangers are dependable and powerful with or without fluid separation, American Wheatley HVAC has what you need to complete your projects.

What is a Heat Exchanger?

A heat exchanger is a device that transfers thermal heat from one medium to another. Often this device is manufactured into numerous types of Heat Exchangers such as Shell & Tube and Plate & Frame. All exchangers are an important part of assisting in cooling and heating of homes and business, but also help in machines work more efficiently.

What types of Heat Exchangers are available?

American Wheatley HVAC offers a full range of Shell & Tube and Plate & Frame heat exchangers which affords higher efficiencies, lower fouling, and modular construction that can easily be field modified. The high turbulence of a plate heat exchanger reduces fouling risks while increasing performance. An optimized PHE will be ½ the size (or less) than an equivalent shell & tube while reaching approach temperatures as low as 2°F. American Wheatley’s shell & tube exchangers range from size 4″ through 30″.

Shell and Tube

Shell &Tube Heat Exchangers consist of a large number of small tubes which are located within a cylindrical shell. These tubes are positioned into cylinders using a tube bundle that is often referred to as “tube sticks” which can either have fixed tube plates or a floating tube stack which allows the tube bundle to expand and contract with varying heat conditions.

Standard Features

- Constructed in accordance with ASME Section VIII

- U-Tube construction

- High degree of flexibility in materials to meet varying conditions

- Available in 2. 4, or 6 pass construction

- All fabrication done in-house

- National board registration

Optional Features

- Additional materials for heads, tubesheets, baffles, and tie rods

- CRN registration

- Optional saddles

- Computerized selections available through authorized HVAC representatives

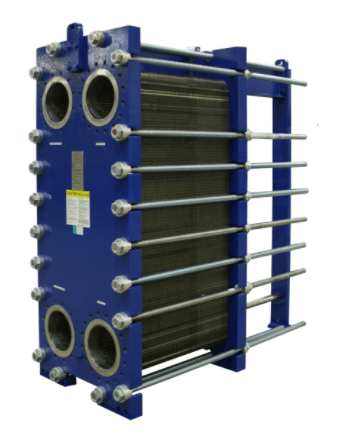

Plate and Frame

Plate Heat Exchangers are operated similarly to Shell & Tube Heat Exchangers, though plates are used instead of tubes. These plates are usually blazed or gasketed depending on the application and fluids being used. This more compact and stainless steel option makes them ideal for use in refrigerants or in food and beverage processing.

Capability

- Port diameter sizes from 1″ to 20″

- Up to 20,000 GPM (4,450 m³/hr)

- Maximum pressure rating of 450 psi

- Maximum temperature rating of 374°F (190°C)

Features

- Modular frame design allows for easy plate pack modification if the working medium or thermal requirements change.

- Optimized plate corrugation ensures even flow distribution across the entire plate surface.

- Tool-less and adhesive-free gaskets for quick maintenance.

- Self-aligning plate pack geometry virtually eliminates plate pack problems even after repeated service.

How Do You Install a Heat Exchanger?

As with any installation, be sure to allow sufficient clearance at the end of the unit for removal or tub bundle. Install the unit so that the pipe connections can be made without forcing them to fit into place. Next, appropriately install the valves and by-passes to permit both the shell & tube bundle to be shut off for inspection, repairs, and cleaning. Finally, the tubing must be full of water before introducing steam or hot water into the shell, otherwise flashing or noise may occur.

Prior to start-up, all nuts should be checked to prevent leaks and blown gaskets. Open the cold side first, then gradually start the hot side, bringing unity to the operating conditions. Always remember to use caution when starting up the heat exchanger and to slowly start up the device to avoid temperature shock to the device.

Need Further Information?

We, at American Wheatley, offer a wide range of options for Heat Exchangers for various usages. Don’t hesitate to contact us for any questions you may have as we are happy to help find the right solution for you!